Basic technology

Press-fit technology, which has been around for some 25 years now, is a solderless connection method. It consists in force fitting an oversized contact pin into the plated through hole of a printed circuit board (PCB). The high radial pressure produces a deformation, resulting in a gas-tight electrical connection of high quality.

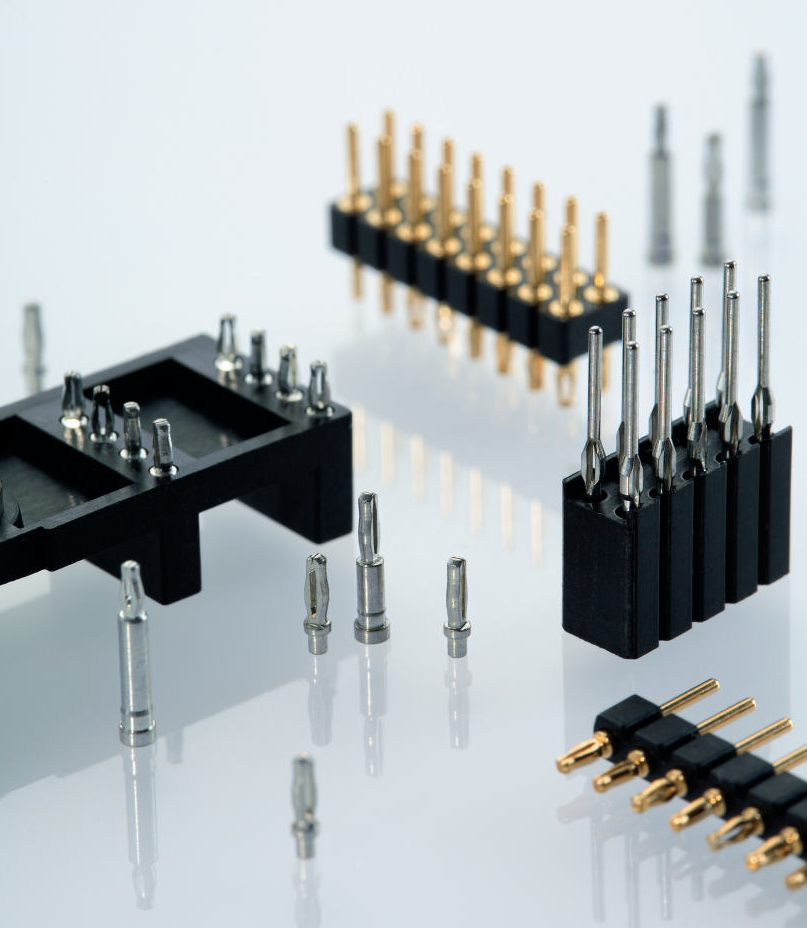

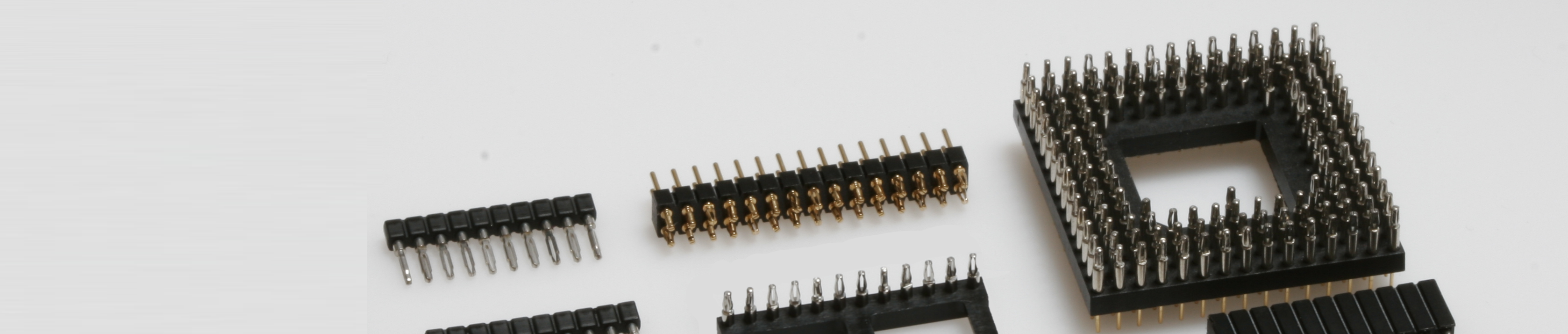

Compliant press-fit technology by PRECI-DIP

We have been producing contacts, sockets and connectors with press-fit terminations for over ten years.

The specific design of our compliant pin is based on a «modified eye of a needle» principle with particular attention paid to material geometry, elasticity characteristics, and surface finish. Its main features are:

- -lastic deformation over the total range of the hole tolerance

- High retention force, in spite of the low insertion force (well below generally admitted maximum values)

- Gas-tight contact zone without any damage (chipping) to hole metallisation

- Low, constant electrical contact resistance

- Complies with IEC60352-5 standard

They are available for plated hole diam eters of 0.6, 0.9,1.0 and 2.44 mm, according to IEC standards. They are compatible with PCB finishes in tin, copper, or gold over nickel.