A perfect alternative to conventional connections solutions

PRECI-DIP is a world leader in design and manufacturing of Spring Loaded Contacts. We offer a full range of products in consumer, industry, medical, MIL Aero and automotive applications.

PRECI-DIP Spring-loaded Contact Technology

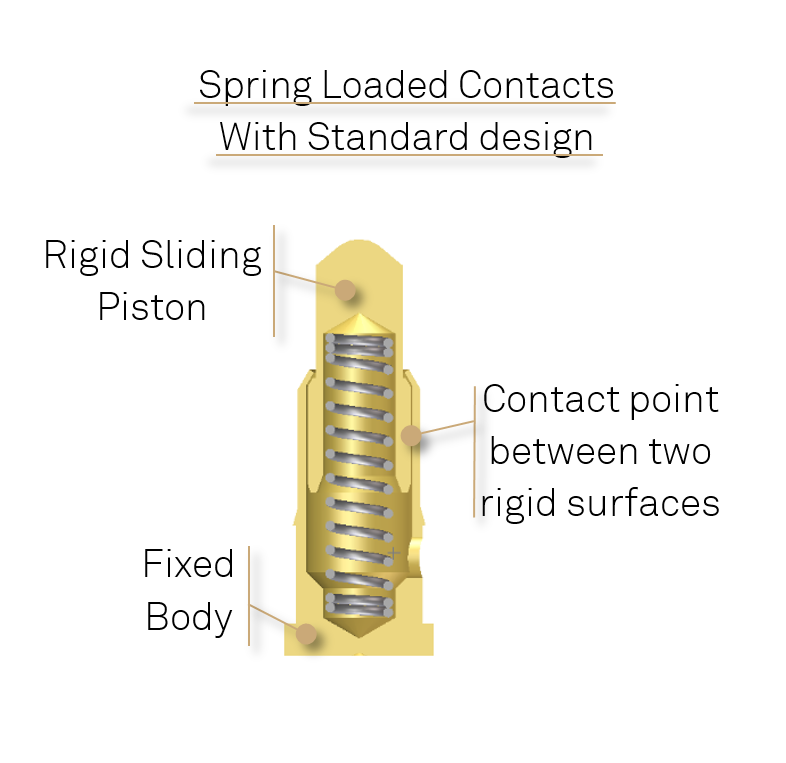

PRECI-DIP spring-loaded contacts are made of a contact body or barrel, a piston and an helical compression spring. The electrical contact is established by the pressure against a fixed, flat area called the pad connector.

PRECI-DIP an evolving line

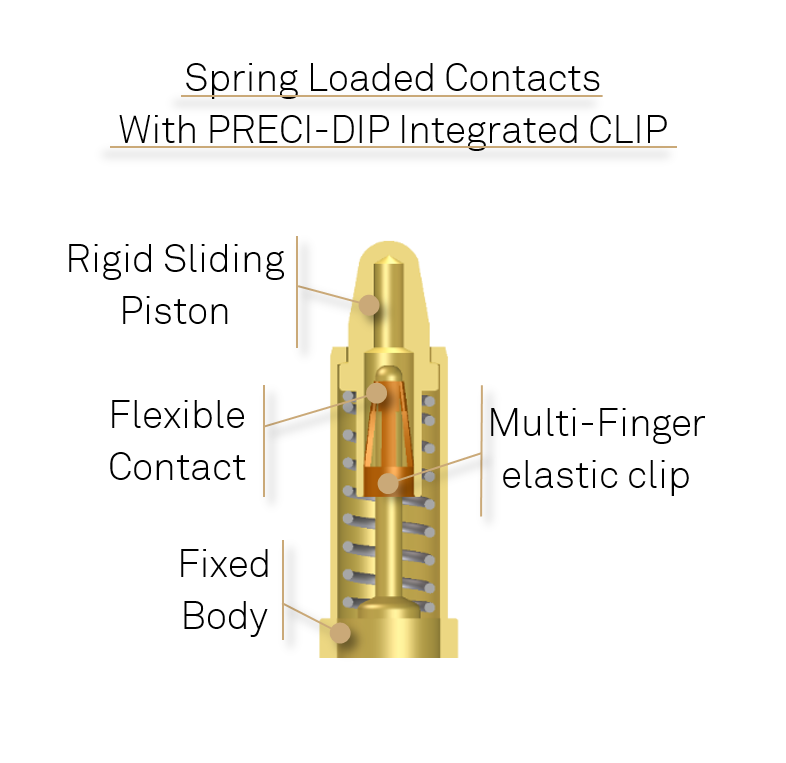

Based on this initial model, we have developed additional designs featuring particular advantages:

– Contacts with a slant. These designs lead to raidal force on the pidton, resulting in a lower ohmic resitance.

– Patented coaxial or in-line designs with integrated multifinger sliding clip establishing electrical continuity between body and piston. The electrical multipoint connection between the

mobile piston and the clip guarantees low, stable electrical resistance values without micro-discontinuities, even when the piston is moving or in case of vibrations, this assuring maximum reliability. See standard Serie 0900-CLIP using this high performance technology.

Comparaison between two technologies

A rigid contact point will disconnect under shock and vibration conditions. This solution is only suitable in static-mode and low current applications.

An integrated Multi-Finger elastic clip establishes a reliable and efficient multi point connection between body and piston. Flexible contact is compliant to shock and vibration up to 2000Hz or more, and capable to handle currents.

See standard Serie 0900-CLIP using this high performance technology. Want to know more ? Watch the Video.

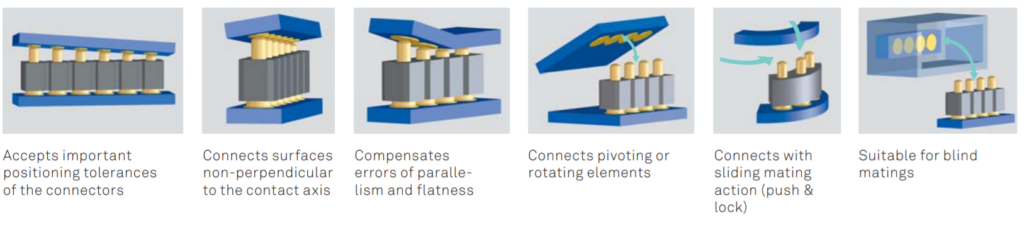

Advantages of Spring Loaded Contacts

Double-Sided Spring Pins

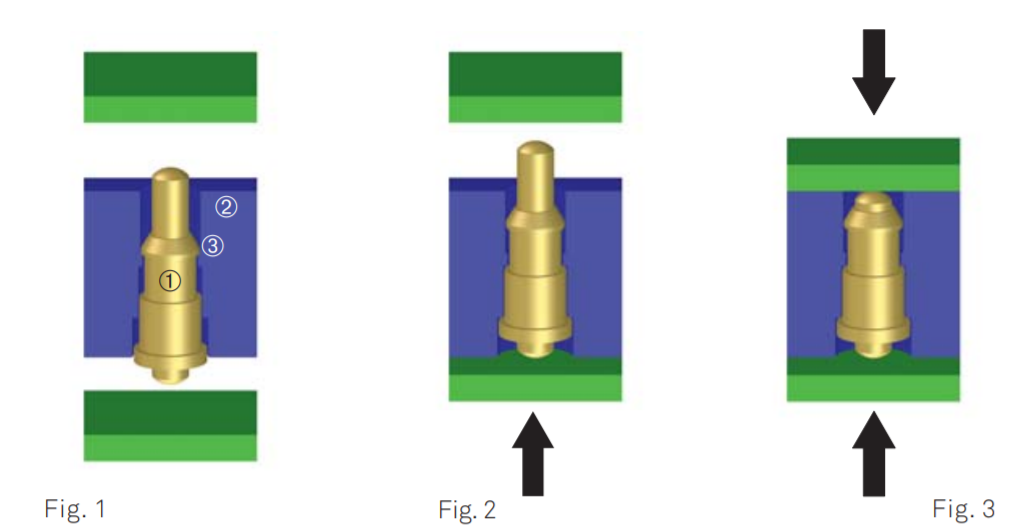

A solderless connecting system with double-sided pressure connection (Fig.1).

The conventional spring-loaded contact (SLC) is mounted in a frame (housing).

The barrel has a groove behind a retention barb. The first contact surface is positioned on one side of the SLC (Fig. 2).

The second contact surface will actuate the spring-loaded

contact. An equal contact pressure applies on both surfaces

(Fig. 3).

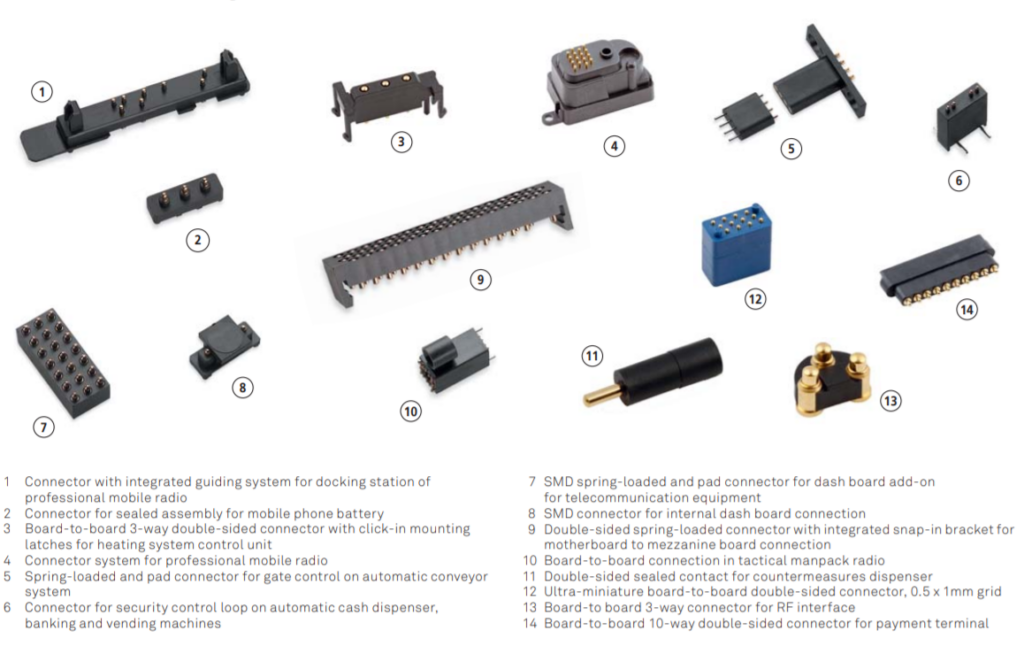

Examples of connector

Applications in telecommunications, automation, industrial, transportation, testing, medical, aerospace, military equipments and consumer goods.